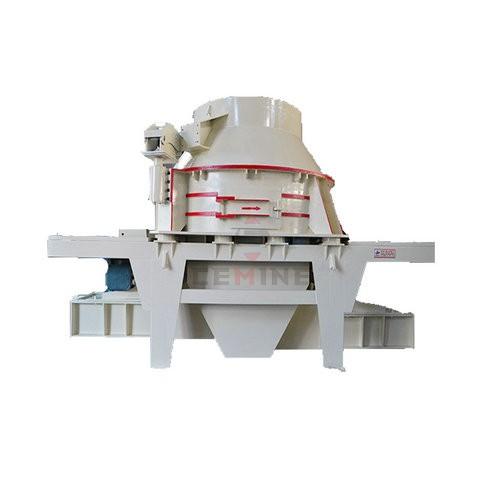

Description

Material from hopper into the sand machine,the material will be divided into two parts by the distributor,part of the feeder into the middle of the high-speed rotation of the impeller,the rapid acceleration in the impeller,the acceleration up to hundreds of times the acceleration of gravity,and then at 60-70m/s from the impeller three uniform flow of the projectile out,first with the distributor around the self-falling part of the materials impact crushing, and then hit the vortex also to change its movement direction,deflecting downward movement,from the impeller flow out of the material to form a continuous material curtain.Such a piece of material in the vortex crushing chamber by two times as many times the probability of impact,friction and grinding crushing effect.The broken material is discharged from the lower discharge port. In the whole crushing process,the material is self impact,friction and crushing,which reduces the angle of pollution,to extend the mechanical wear time. Vortex cavity inside the fresh air from the cycle,eliminating the dust pollution.

Technical Parameter

|

Model |

Max Feed Size(MM) |

Power(KW) |

Shaft Speed(R/MIN) |

Capacity(T/H) |

|

VSI-6020 |

26 |

2X37/55 |

2000/2600 |

8-50 |

|

VSI8620 |

35 |

2X75/110 |

1000/1450 |

60-150 |

|

VSI9526 |

40 |

2X132/160 |

950/1200 |

100-260 |

|

VSI1210 |

45 |

2X200/220 |

950/1200 |

200-350 |

|

VSI5120 |

50 |

2X250 |

800/1000 |

300-460 |